Whistleblower system

We won’t tolerate any kind of violation of the law (be it corruption, fraud, theft, illegal agreements or other illegal actions) nor discrimination nor violations of internal regulations, in particular our Code of Conduct.

Our employees as well as external third parties have the opportunity to report violations anonymously and in confidence, including in relation to incidents in the supply chain.

Such reports can be sent to us via various communication channels.

Via the OWG whistleblower system (IT tool)

https://owg.grc-cloud.de/Meldung?lang=EN reports are possible around the clock in German and English and anonymously.

Phone

Tips can also be submitted by telephone in German and English at +49 8121 707-17332 during normal business hours (Mon to Thu 9:00 a.m. to 5:00 p.m., Fri 9:00 a.m. to 12:00 p.m.).

e-mail

compliance@tiptop.de

Mail

OWG Beteiligungs AG, Legal Department, Gruber Str. 65, 85586 Poing / Germany

On request of the informant, a personal meeting is also possible.

All reports are checked carefully. If necessary, we will take corrective action and use such reports to further improve our compliance system.

We assure that we will not take any action to identify anonymous whistleblowers unless our whistleblower system is used fraudulent.

Our procedural regulations for submitting information and processing reports can be found here.

Our data protection information for whistleblowers here.

Glove-Sleeve System

The glove sleeve system consists of a cuff that is attached to a glove using an adapter ring. The cuff and glove materials can be combined according to requirements. If the glove is damaged, it can be replaced, while the cuff can still be used. The total length of the glove sleeve system is approx. 800 mm.

We offer the following protective gloves for the system:

Jugitec B 03/05/07

- Version: rough and smooth

- Size: 7 / 8 / 9 / 10 / 11

- Length: 350 mm

- Hand shape: fully anatomical

- WandWall thicknesses: 0,3 / 0,5 / 0,7 mm

Jugitec BV 03/07

- Version: smooth

- Size: 7 / 8 / 9 / 10 / 11

- Length : 300 / 350 mm

- Hand shape: fully anatomical

- Wall thicknesses: 0,3 / 0,7 mm

Jugitec H (0,4 mm)

- Version: smooth

- Size: 9 / 10

- Length : 350 mm

- Hand shape: fully anatomical

- Wall thicknesses: 0,4 mm

We offer the following cuffs for the system:

Jugitec H

- Wall thicknesses: 0,4 mm

- Length: 520 mm

- rolled edge: on the port side

- Wrist port diameter: 90-100mm

- Port diameter shoulder: on request

Jugitec B

- Wall thicknesses: 0,4 mm

- Length: 520 mm

- rolled edge: on both sides

- Wrist port diameter: 90-100mm

- Port diameter shoulder: on request

Jugitec ISOflex

- Wall thicknesses: 0,5 mm

- Length: 520 mm

- rolled edge: on both sides

- Wrist port diameter: 90-100mm

- Port diameter shoulder: on request

Adapter Ring

- Material: POM

- Dimensions inside: 10,0 cm

- Dimensions outside: 11,0 cm

- Height:4 cm

O-Ring

- Material: EPDM

- Measurements: 85x5 mm

Mounting instructions

Slide the adapter ring from the large diameter into the cuff until the rolled edge of the small diameter sits on the 1st groove of the adapter ring.

The rolled edge of the cuff sits firmly in the 1st groove of the adapter ring.

Position the rolled edge of the glove in the 3rd groove of the adapter ring.

Clamp the O-ring onto the center groove of the adapter ring. The glove sleeve system is ready for use.

Contactform technical rubber goods

Traide Fairs

| Messe | Datum |

|---|---|

| 2023 | |

| Interphex, New York | 25.04.-27.04.2023 |

| AGS, Las Vegas | 24.07.-27.07.2023 |

| A+A, Düsseldorf | 23.10.-27.10.2023 |

| 2024 | |

| Jobs for Future, Mannheim |

22.02. – 24.02.2024 |

|

Interphex, New York |

16.04. – 18.04.2024 |

| ACHEMA, Frankfurt am Main |

10.06. – 14.06.2024 |

| AGS, Boston |

22.07. – 25.07.2024 |

| Expoprotection, Paris |

5.11. – 07.11.2024 |

| 2025 | |

| A+A, Düsseldorf |

4.11.-07.11.2025 |

Information requirements

The protection of your personal data is of particular concern to us. We therefore process your personal data (in short "data") exclusively on the basis of the statutory provisions. With this data protection declaration we want to inform you about the processing of your data in our company and the data protection claims and rights to which you are entitled comprehensively in the sense of Art. 13 of the European Data Protection Regulation (EU DS-GVO).

1. Who is responsible for data processing and whom can you contact?

Responsible is

Jung Gummitechnik GmbH

Robert-Bosch-Str. 2-6, 64683 Einhausen

Phone: +49 (0) 6251 9634 0

Fax: +49 (0) 6251 9634 19

E-Mail: info@jung-gt.de

The company data protection officer is

Bernhard Brunner

Projekt 29 GmbH & Co. KG

Ostengasse 14

93047 Regensburg

E-Mail: anfragen@projekt29.de

Phone: 0941-2986930

2. Which data are processed and from which sources do these data originate?

We process the data that we have received from you as part of the contract initiation or processing, on the basis of consent or as part of your application to us or as part of your employment with us.

Personal data includes:

Your master/contact data, for customers this includes e.g. first and last name, address, contact data (e-mail address, telephone number, fax), bank data.

In the case of applicants and employees, this includes, for example, first and last name, address, contact data (e-mail address, telephone number, fax), date of birth, data from curriculum vitae and references, bank data, religious affiliation.

In the case of business partners, this includes, for example, the designation of their legal representatives, company name, commercial registration number, VAT number, company number, address, contact person contact data (e-mail address, telephone number, fax), bank data.

In addition, we also process the following other personal data:

- Information about the nature and content of contract data, order data, sales and document data, customer and supplier history, and consulting records,

- Advertising and sales data,

- Other data that we have received from you in the course of our business relationship (e.g. in customer meetings),

- data that we generate ourselves from master / contact data and other data, such as by means of customer demand and customer potential analyses,

- documenting your consent to receive newsletters, for example.

3. For what purposes and on what legal basis are the data processed?

We process your data in accordance with the provisions of the General Data Protection Regulation (GDPR) and the Federal Data Protection Act 2018, as amended:

- for the fulfillment of (pre-)contractual obligations (Art. 6 para. 1lit.b DS-GVO):

The processing of your data takes place for the contract processing online or in one of our branches, for the contract processing of your staff in our company. In particular, the data is processed during business initiation and during the execution of contracts with you.

- for the fulfillment of legal obligations (Art. 6 para. 1 lit.c DS-GVO):

Processing of your data is necessary for the purpose of fulfilling various legal obligations, e.g. from the German Commercial Code or the German Fiscal Code.

- for the protection of legitimate interests (Art. 6 para. 1 lit.f DS-GVO):

Based on a balancing of interests, data processing may take place beyond the actual fulfillment of the contract to protect legitimate interests of us or third parties. Data processing for the protection of legitimate interests occurs, for example, in the following cases:

- advertising or marketing (see No. 4),

- measures for business management and further development of services and products;

- Maintaining a group-wide customer database to improve customer service

- in the context of legal prosecution.

- within the scope of your consent (Art 6 para. 1lit.a DSGVO):

If you have given us consent to process your data, e.g. to send you our newsletter.

4. processing of personal data for advertising purposes

You may object to the use of your personal data for advertising purposes at any time, either in whole or in respect of individual measures, without incurring any costs other than the transmission costs in accordance with the basic rates.

We are entitled under the legal conditions of § 7 Abs.3 UWG to use the e-mail address that you provided when concluding the contract for direct advertising for our own similar goods or services. You will receive these product recommendations from us regardless of whether you have subscribed to a newsletter.

If you do not wish to receive such recommendations from us by e-mail, you can object to the use of your address for this purpose at any time without incurring any costs other than the transmission costs according to the prime rates. A message in text form is sufficient for this purpose. Of course, an unsubscribe link is always included in every e-mail.

Use of a Service Provider for Cold Calling

To inform you about our products and services, we engage a specialized service provider for cold calling. This provider acts on our behalf and in accordance with a contractual agreement as a processor under Article 28 of the GDPR.

The service provider processes personal data exclusively based on our instructions and in compliance with applicable data protection regulations. The processing is carried out for the purpose of contacting you via phone or in writing to inform you about our offerings, provided this is legally permissible (e.g., based on an existing business relationship in accordance with GDPR Article 6(1)(b) or your explicit consent in accordance with GDPR Article 6(1)(a)).

5. who receives my data?

If we use a service provider in the sense of commissioned processing, we nevertheless remain responsible for the protection of your data. All commissioned processors are contractually obligated to treat your data confidentially and to process it only in the context of providing the service. The processors we commission receive your data insofar as they require the data to fulfill their respective service. These are, for example, IT service providers that we require for the operation and security of our IT system as well as advertising and address publishers for their own advertising campaigns.

Your data is processed in our customer database. The customer database supports the enhancement of the data quality of the existing customer data (duplicate cleansing, moved/deceased indicators, address correction), and enables the enrichment with data from public sources.

This data is made available to the Group companies to the extent necessary for contract processing. Customer data is stored separately on a company-by-company basis, with our parent company acting as a service provider for the individual participating companies.

In the event of a legal obligation and in the context of legal prosecution, authorities and courts as well as external auditors may be recipients of your data.

In addition, insurance companies, banks, credit agencies and service providers may be recipients of your data for the purpose of initiating and fulfilling contracts.

6. how long will my data be stored?

We process your data until the termination of the business relationship or until the expiry of the applicable statutory retention periods (such as from the German Commercial Code, the German Fiscal Code, the German Home Act or the German Working Hours Act); furthermore, until the termination of any legal disputes in which the data is required as evidence.

7. are personal data transferred to a third country?

In principle, we do not transfer any data to a third country. A transfer takes place in individual cases only on the basis of an adequacy decision of the European Commission, standard contractual clauses, appropriate guarantees or your express consent.

8. what data protection rights do i have?

You have a right to information, correction, deletion or restriction of the processing of your stored data at any time, a right to object to the processing as well as a right to data portability and to lodge a complaint in accordance with the requirements of data protection law.

Right to information:

You can request information from us as to whether and to what extent we process your data.

Right of rectification:

If we process your data that is incomplete or incorrect, you can request that we correct or complete it at any time.

Right of deletion:

You can demand that we delete your data if we process it unlawfully or if the processing disproportionately interferes with your legitimate interests of protection. Please note that there may be reasons that prevent immediate deletion, e.g. in the case of legally regulated retention obligations.

Irrespective of the exercise of your right to deletion, we will delete your data immediately and completely, insofar as there is no legal or statutory obligation to retain data in this respect.

Right to restriction of processing:

You may request us to restrict the processing of your data if

- You dispute the accuracy of the data for a period of time that allows us to verify the accuracy of the data.

- the processing of the data is unlawful, but you refuse erasure and request restriction of data use instead,

- we no longer need the data for the intended purpose, but you still need this data to assert or defend legal claims, or

- You have objected to the processing of the data.

Right to data portability:

You may request that we provide you with the data you have provided to us in a structured, commonly used and machine-readable format and that you may transfer this data to another controller without hindrance from us, provided that

- we process such data on the basis of consent given by you, which may be revoked, or for the performance of a contract between us, and

- this processing is carried out with the aid of automated procedures.

If technically feasible, you may request that we transfer your data directly to another data controller.

Right to object:

If we process your data for legitimate interest, you can object to this data processing at any time; this would also apply to profiling based on these provisions. We will then no longer process your data unless we can demonstrate compelling legitimate grounds for the processing that override your interests, rights and freedoms, or the processing serves to assert, exercise or defend legal claims. You may object to the processing of your data for the purpose of direct marketing at any time without giving reasons.

Right of appeal:

If you are of the opinion that we are violating German or European data protection law in the processing of your data, please contact us so that we can clarify any questions. Of course, you also have the right to contact the supervisory authority responsible for you, the respective state office for data protection supervision.

If you wish to exercise any of the aforementioned rights against us, please contact our data protection officer. In case of doubt, we may request additional information to confirm your identity.

9. am I obliged to provide data?

The processing of your data is necessary for the conclusion or fulfillment of your contract entered into with us. If you do not provide us with this data, we will usually have to refuse to conclude the contract or will no longer be able to perform an existing contract and consequently have to terminate it. However, you are not obliged to give your consent to data processing with regard to data that is not relevant for the fulfillment of the contract or that is not required by law.

From the founding to today

An overview of the company history of JUNG

The company was founded by Friedrich JUNG in Lorsch

Expansion of production in Lorsch

Jugitec is registered as a trademark

Certification according to DIN ISO 9001

Move to Einhausen

Sale of JUNG Gummitechnik GmbH to WAGU Gummitechnik GmbH

Expansion of the Einhausen location

Expansion with a new location in Warstein

Certification according to DIN ISO 14001

Integration into the OWG network

JUNG Rubbertec® is registered as a trademark

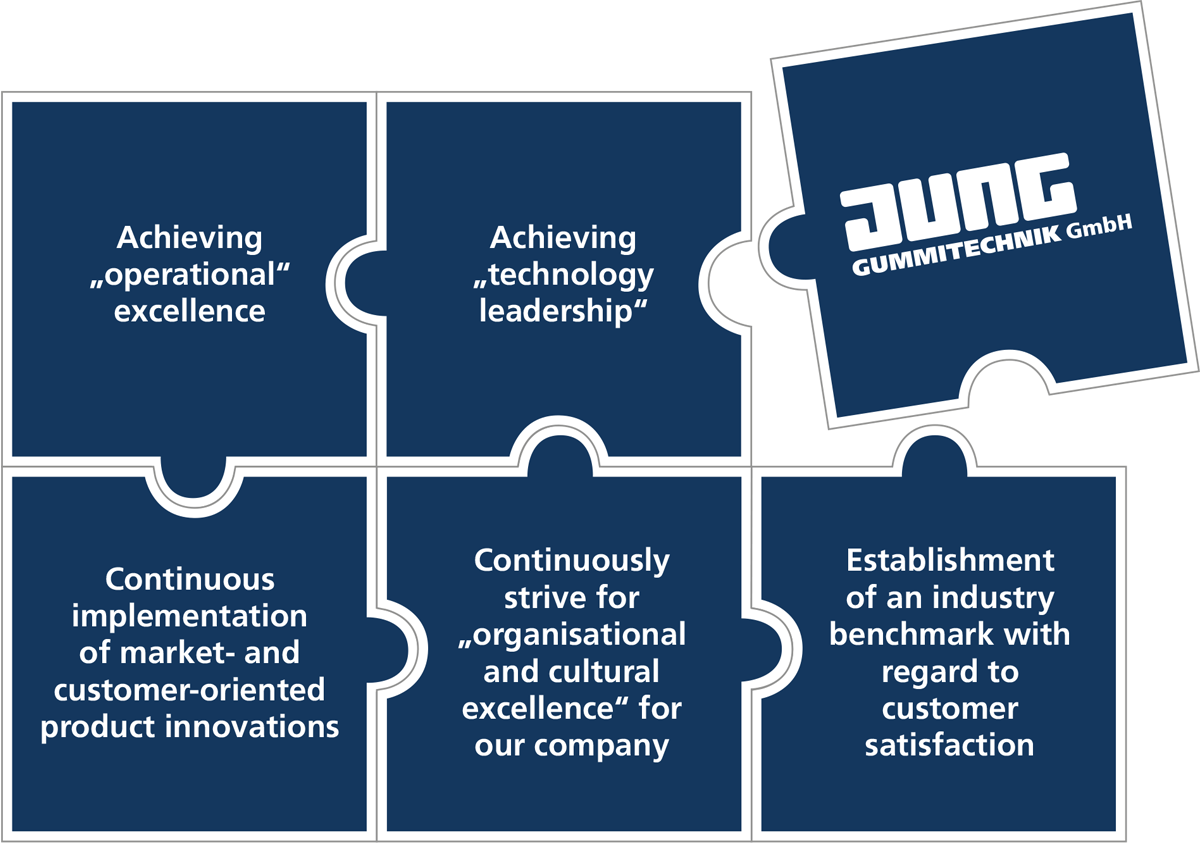

Jung Gummitechnik GmbH

Healthy structures at all levels and in cooperation with all our partners form the basis for our success in sensitive markets

WE STAND FOR THE HIGHEST PRODUCT QUALITY IN TECHNICAL RUBBER GOODS

“MADE IN GERMANY” ALONG THE ENTIRE PRODUCTION PROCESS

We manufacture our technical rubber goods completely “made in Germany” and stand for the best quality. We produce our technical rubber goods exclusively at our site in Einhausen and can therefore accompany the creation of our rubber components and moulded parts through to the finished product at every stage and ensure the enforcement of high quality standards. Proven regional partners cooperate with us in the production of tools for applications such as special parts or moulded hoses. We are strong in transforming individual customer enquiries and requirements into a solution after qualified consultation. From individual parts to small series, we can serve all customer requirements. On request, we design our products to national and international standards.

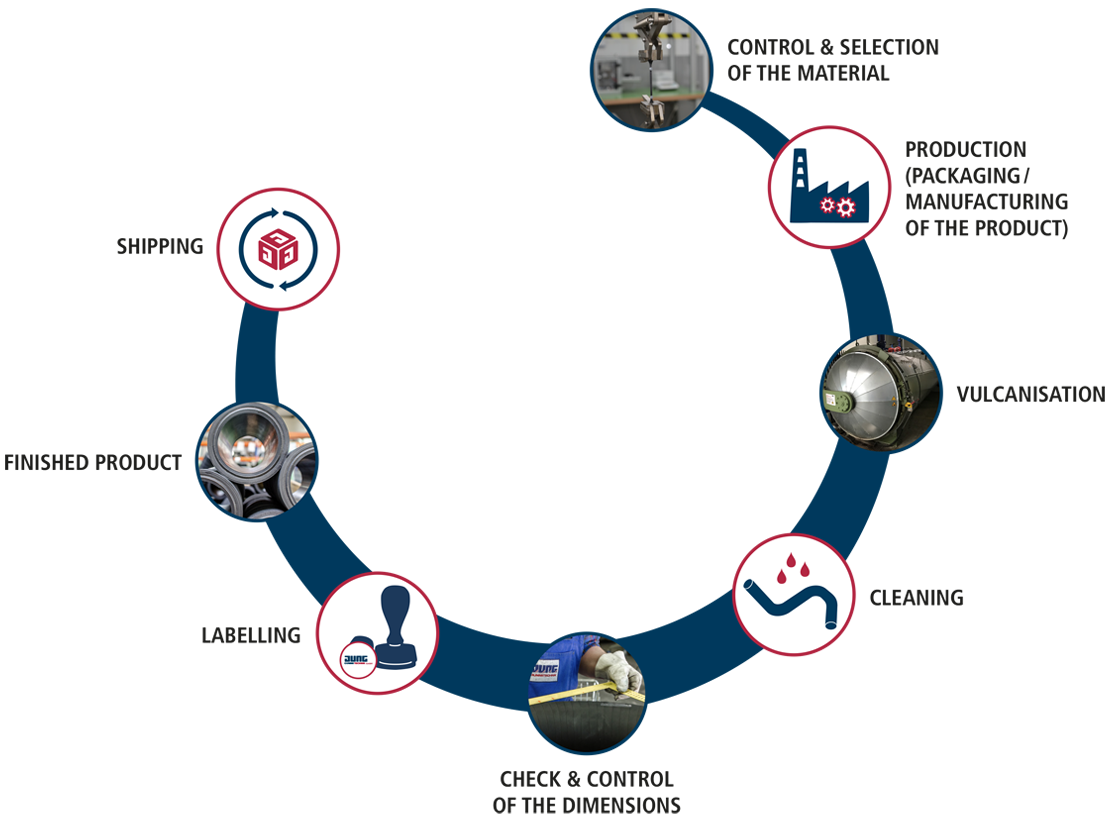

CONTROL AND MATERIAL SELECTION FOR TECHNICAL RUBBER GOODS:

- We undergo regular external controls to ensure consistent quality requirements.

- The material selection is made in close consultation with our proven compounders.

- A strict incoming goods inspection takes place before processing.

- Technical rubber goods are usually counter-checked and released by the customer with an initial sample test report (acceptance test certificate 3.1 DIN EN 10204) for correct production and implementation.

PRODUCTION OF TECHNICAL RUBBER GOODS:

- For hoses, elbows and moulded parts, we take care of the application-specific, individual implementation according to customer requirements and drawings.

- We ensure process reliability. Environmental influences are precisely controlled to enable consistent production conditions.

- The vulcanisation process of hoses and elbows takes place in a boiler that has been adapted to us. Moulded parts are vulcanised separately by a pressure and pressing process.

- All technical rubber goods are cleaned by adapted processes.

TESTING AND CHECKING THE MASS OF TECHNICAL RUBBER GOODS

- Depending on the requirements, an outgoing goods inspection of up to 100 percent is carried out. Properties such as length, diameter, weight, optical integrity, tightness and wall thickness are checked.

- Our in-house testing laboratories offer the possibility to test all mechanical properties such as pressure and vacuum, conductivity, tensile and tear propagation and abrasion resistance on site upon request.

LABELLING AND PACKAGING OF TECHNICAL RUBBER GOODS:

- The marking of hoses, elbows, moulded articles and other components is individually possible.

- Each product is inspected after completion and cut and packed according to specifications so that it can then be handed over to the respective shipping companies.

- For example, FDA conformity and electrical conductivity can be confirmed with a certificate on request. For technical rubber goods we can issue a works certificate according to DIN EN 10204 – 2.1, 2.2 and 3.1.

- Our technical rubber goods are in demand all over the world and find their way to their respective destinations by road, water or air. If necessary, export processing is carried out in cooperation with our customers by our Order Processing department.

We are also happy to issue factory certificates on request:

- Fire protection

- Pressure test

- Initial sample inspection report

- Conductivity

- Food certificate

- Factory certification according to 2.1; 2.2, 3.1

HIGHEST QUALITY LEVEL IN SPECIAL GLOVES AND PROTECTIVE GLOVES FOR GLOVEBOX, INSULATOR AND RABS APPLICATIONS AS WELL AS OCCUPATIONAL HEALTH AND SAFETY

STATE-OF-THE-ART MANUFACTURING PROCESSES AND 100% CONTROLS ENSURE QUALITY

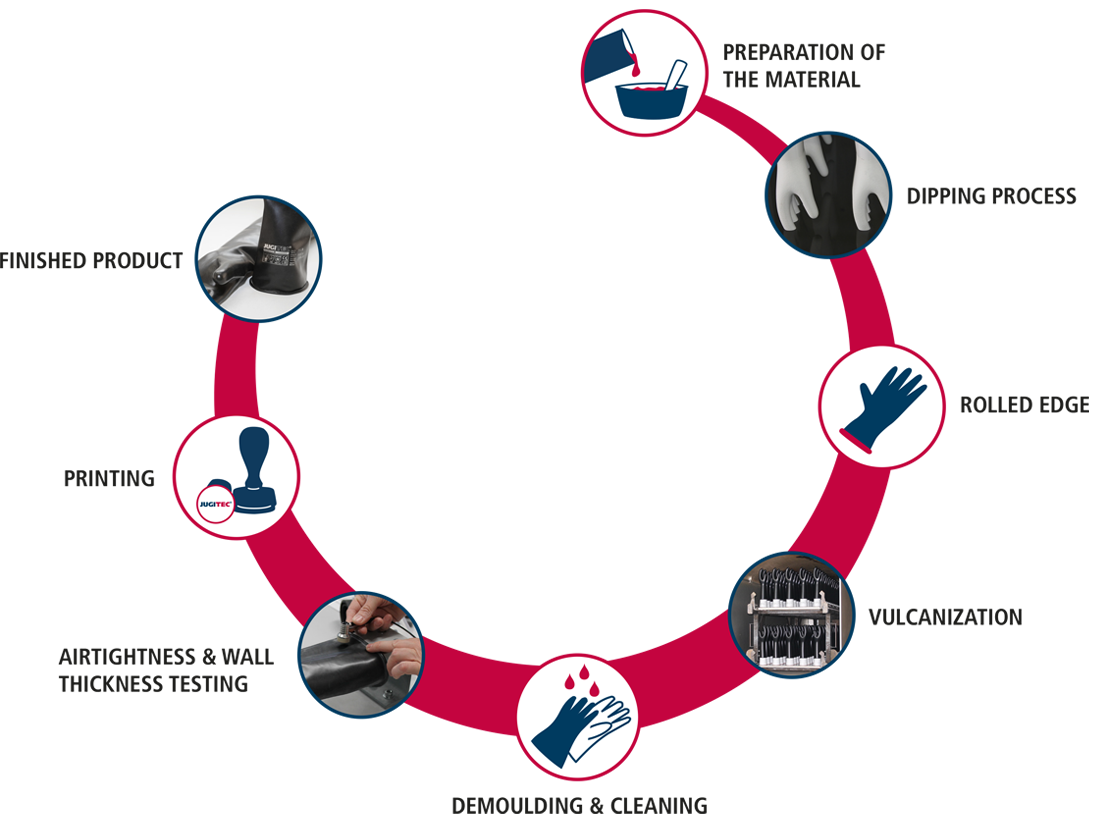

Our type-examination-tested glovebox gloves and our special protective gloves for category III occupational safety (chemical occupational safety as well as insulating electrician's gloves) are manufactured using the dipping process and convince with the highest quality. The dipping processes are continuously monitored – taking into account all relevant parameters – and are kept at the most modern level to meet all requirements. In this way, we can ensure consistently high quality for every single new batch. State-of-the-art production processes and careful handling of the resources we use ensure that our products are manufactured ecologically and sustainably.

We also manufacture our special gloves and protective gloves completely “made in Germany” and thus ensure consistently high quality in this segment as well. Our production is carried out exclusively at our two locations in Germany (Einhausen and Warstein) – allowing us to control and monitor production at every stage. We are certified according to DIN ISO 9001:2015 and ISO 14001:2015 and ensure sustainability as well as the best possible process flows. In order to be able to offer high-quality and safe protective gloves made of rubber (caoutchouc, elastomer polymers), we have committed ourselves to consistent production monitoring – all this taking due account of customer-specific standards and compliance with the highly demanding GMP guidelines.

CONTROL AND MATERIAL SELECTION FOR GLOVEBOX, INSULATOR AND RABS GLOVES AS WELL AS PROTECTIVE WORK GLOVES (CHEMICAL WORK PROTECTION, INSULATING ELECTRICIAN GLOVES):

- Our protective glove products are externally controlled by the highest safety standards for personal protective equipment (PPE). Module D monitoring of all PPE articles and type examinations at prescribed intervals are carried out by externally notified bodies.

- Regular external controls prove the consistent quality requirement.

- The material selection, the consistent quality and adherence to the recipes of the respective rubber compound are realised in close consultation with our proven compounders.

- Before the rubber is processed, a strict incoming goods inspection takes place.

PRODUCTION OF GLOVEBOX, INSULATOR AND RABS GLOVES AS WELL AS INDUSTRIAL SAFETY GLOVES (CHEMICAL WORK PROTECTION, INSULATING ELECTRICIAN GLOVES):

- We ensure process reliability. Environmental influences are closely controlled to enable consistent production conditions of our protective work gloves.

- Our special gloves undergo vulcanisation in a cauldron adapted to the specific requirements.

- All gloves are cleaned by adapted processes such as tumbling, washing or similar.

TESTING AND CHECKING THE MASS OF GLOVEBOX, INSULATOR AND RABS GLOVES AS WELL AS INDUSTRIAL SAFETY GLOVES (CHEMICAL WORK PROTECTION, INSULATING ELECTRICIAN'S GLOVES)

- We take care of air tightness and wall thickness tests of our finished special gloves, perform a dimensional check of the length, material thickness (five measuring points) and the rolling rim diameter of the rubber glove.

- We carry out an airtightness test in accordance with test method B/DIN EN 421 on the industrial safety gloves. The quality system for Jugitec products allows complete traceability of all material, process and test parameters – for each individual glove and for each user. Test certificates and information sheets on safe handling are enclosed with every delivery.

- The outgoing goods inspection is carried out up to 100 percent, depending on the requirements: The visual inspection is carried out for each individual glove.

- Additional properties such as length, diameter, weight, tightness and wall thickness are checked according to AQL 1.5. In the event of a discrepancy, a 100 per cent check is also carried out.

- Our in-house testing laboratories offer the possibility to test all mechanical properties of the special gloves such as permeation behaviour, pressure and vacuum testing, conductivity, tensile and tear propagation testing, abrasion resistance and puncture resistance on site upon request.

- All the special gloves we make are carefully scrutinised before they are sold. Here, all process parameters are documented and checked in detail by our final inspection. These tests are carried out on the basis of manufacturer's solder, WPZ (factory test certificate), as well as rheological and mechanical material tests. Material and permeation tests are carried out in the company's own test laboratory.

LABELLING, PACKAGING AND SHIPPING OF GLOVEBOX, INSULATOR AND RABS GLOVES AS WELL AS INDUSTRIAL SAFETY GLOVES (CHEMICAL WORK PROTECTION, INSULATING ELECTRICIAN GLOVES):

- The rubber protective gloves are labelled with the type designation, production date and batch number.

- PPE items are labelled with all relevant information such as date of manufacture, batch number and material type or individually on customer request.

- Each protective glove is inspected on completion and cut to specification and packaged in a suitable light protected polybag.

- On request, FDA conformity and electrical conductivity of the protective work glove manufactured by us can be confirmed with a certificate.

- We can issue a Certificate of Conformity (CoC) for glovebox, insulator and RABS gloves.

- Depending on the delivery quantity, the protective gloves are packed according to our own specifications or also at the customer's request and handed over to the selected forwarding agent.

- Our glovebox, insulator and RABS gloves as well as industrial safety gloves are in demand worldwide and make their way to their respective destinations by road, water or air. Export processing is carried out in cooperation with our customers by our Order Processing department.

We are also happy to issue factory certificates on request:

- Certificate of Conformity

- Food certificates such as FDA standard

- Various customer-specific verifications

- CE conformity

TESTING AND LABELLING

The quality system of our Jugitec products allows complete traceability of all material, process and test parameters – for every glove and every user. Test certificates and information sheets on safe handling are enclosed with every delivery.

Schritt

Cleaning the gloves

Schritt

100% visual inspection of the surface

Schritt

Dimensional check of length, material thickness (5 measuring points) and rolling edge diameter

Schritt

Air tightness test according to test method B in accordance with DIN EN 421

Schritt

Labelling with type designation, production date and batch number

Schritt

Packing in suitable light-protected polybag

THESE STANDARDS APPLY TO OUR TECHNICAL RUBBER GOODS

STANDARD-COMPLIANT PRODUCTION AND DELIVERY OF MOULDED PARTS, SPECIAL PARTS AND ASSEMBLIES

Our technical rubber goods are manufactured according to the specifically required standards and regulations as well as the required tolerances. Here you will find an overview of all the standards that apply to our products. If you have any questions about the standards or need your own in-house standard for products, please contact us for more information.

OVERVIEW OF THE COMMON STANDARDS:

- Test certificates:

DIN EN 10204 Metallic products – Types of inspection certificates - Fire protection:

DIN 5510 Part 2: 2009-05 - Railway applications – Fire protection in railway vehicles:

DIN EN 45545-2 - Permissible dimensional deviations (tolerances):

DIN 7715-4 S2 and SL2 - Quality management systems Basics and terms:

DIN EN ISO 9000 - Quality management systems Guide to performance improvement:

DIN EN ISO 9004 - Guideline for audits of quality management/ or environmental management systems:

DIN EN ISO 19011 - Hoses and moulded hoses for cooling water:

DIN 73411 - Storage of rubber products:

DIN 7716